At the end of the Bachelor’s fourth semester, Microengineering students from EPFL have to do a two weeks machining internship during their summer holidays. The internship took place at ETML (school of technical professions in Lausanne). Throughout these two weeks we learned how to use these three main machine-tools:

- Milling machine: to achieve parallelepipedal shapes. Matter is removed by a fast rotating reamer.

- Lathe: to achieve cylindric shapes. Matter is removed by a fixed chisel while the piece rotates.

- Drill: to pierce holes, to chamfer circular edges, to drill, etc. Matter is removed by a rotating drill bit translating vertically.

It featured a lot of techniques such as:

- Brazing: to assembly two pieces by heating them (no fusion) with a neutral flame (oxygen+acetylen at 3200°C) and adding a filler metal (other techniques exists).

- Tapping: done either by hand or with the lathe.

- Threading: done with the lathe (multiple procedures are possible depending on the diametre).

- Sawing: required to quickly remove certain steel parts of pieces without much precision.

- Filling: a lot of filling was necessary to shape certain steel pieces. By using limes with different shapes and grain-sizes (and with a lot of elbow grease) it was possible to obtain very neat surfaces, either flat or curved.

- Micro-measuring: for certain pieces precise tolerances had to be respected. To do so we used precise measurement tools as well as the machines precise positioning systems. The maximal precision usually achievable with the machines at our disposal was 5µm.

- (…)

- Safety: even if properly speaking it is not a technique, working in the workshop quickly made us realize the potential dangers of such environment. So always protect your eyes, ears, skin and avoid stupid moves.

We also had the opportunity to see a CNC (computer numerical control) machine at work, and the way it is configured.

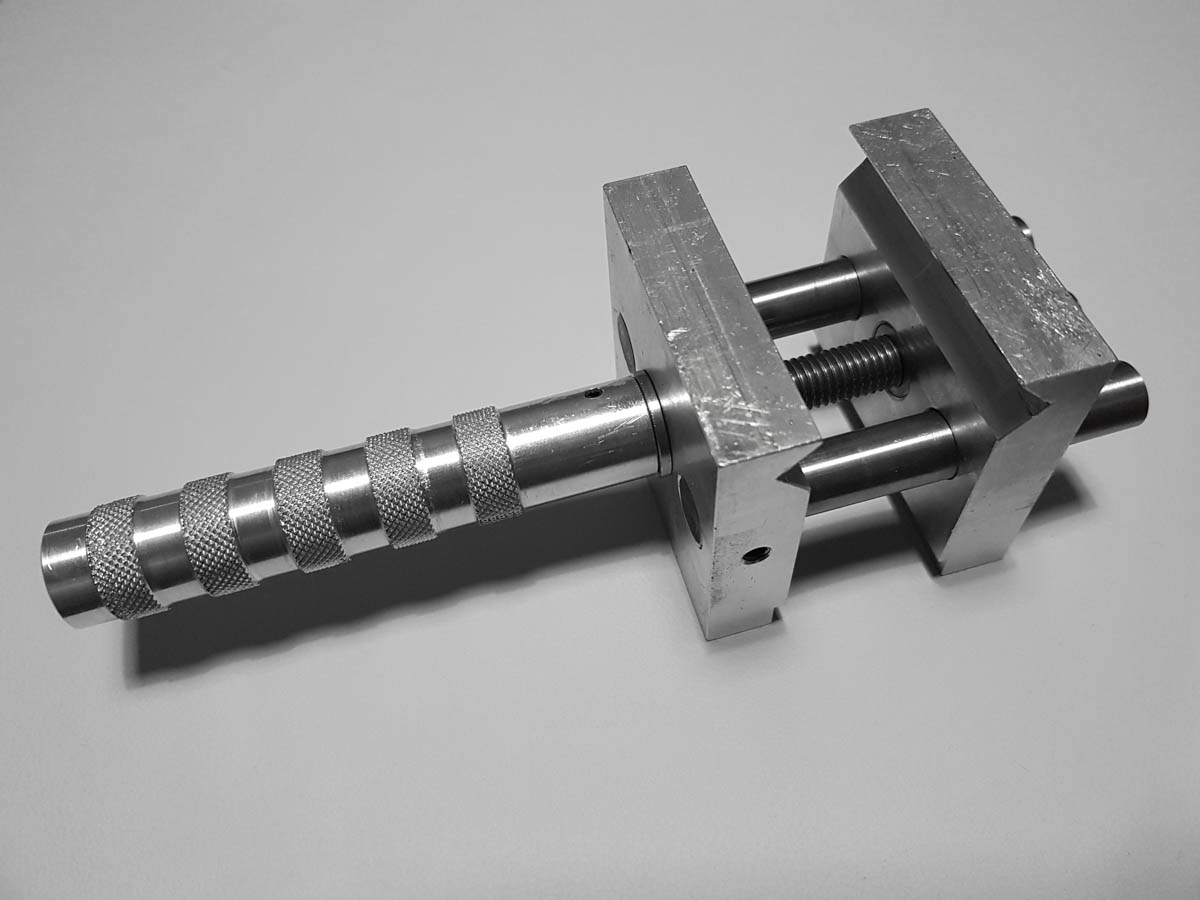

In the end, all the pieces we produced while learning finally assembled into a clamp and a hand vise that we could bring home with us. I am pretty satisfied of mines, and they will remain as a good memory.

Overall this internship has been a really enriching experience, enabling us to put in practice the content of the courses Mechanical Construction I and II. It is indeed paramount that engineers and technicians can communicate well and understand each other’s issues in order to collaborate and produce something. If it was a bit tiring at the beginning (from standing the whole day and manipulating heavy machines), I got used to it pretty fast and enjoyed this more active type of work.